Loading... Please wait...

Loading... Please wait...Our Newsletter

- Home

- Product Profile

Product Profile

|

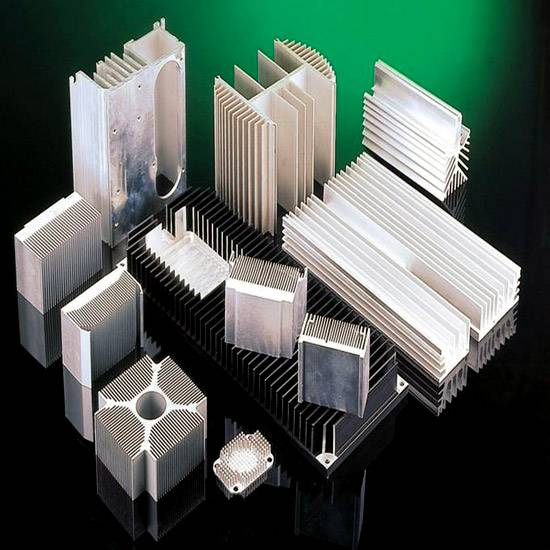

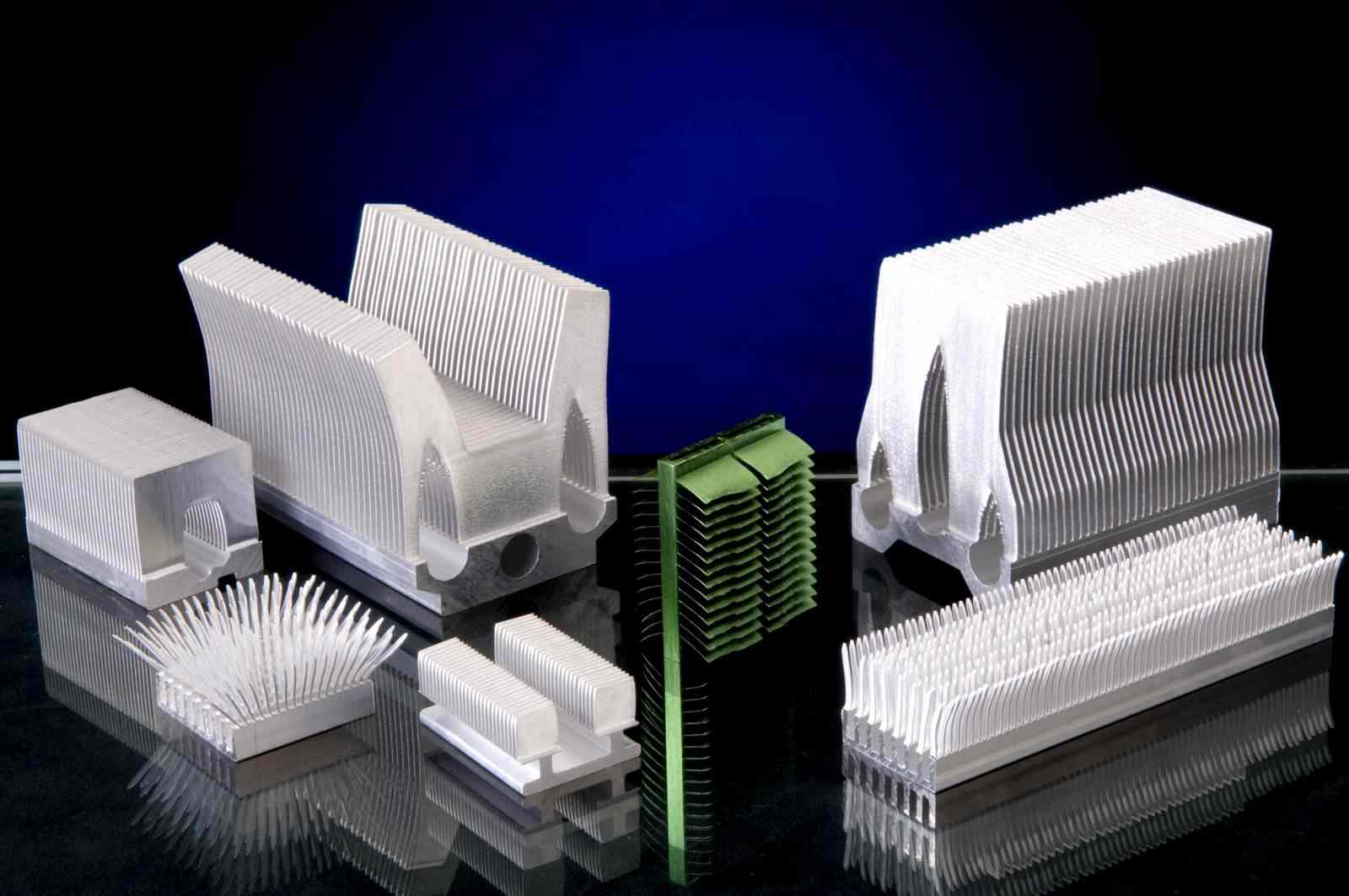

Hoi Po is renowned for its custom made products subject to tight tolerance level and expanding varieties in colour. With immense flexibility towards innovative designs and applications of aluminium extrusion materials, we have successfully satisfied our customers. To name a few, Fujitsu Siemens, Siemens, Sonca-Energizer, Sentry Fire Safe, Celestica, Foster Electric. Our resources are dedicated to manufacturing both Industrial Products and Construction Products in 90:10 ratio. Heatsinks, Electrical Appliances Components, Torch Light Parts, etc have built the reputation of Hoi Po production, whilst window frames, door frames, curtain walls, etc of construction side, though less significant in terms of scale, equally bear the same reputable brand in quality. Uses of Aluminium ExtrusionHoi Po is familiar with aluminium and its variety of use in different industries. With the aid of our extrusion specialist, the special metallic features of aluminium and their instrumental advantages are uncovered in the products of our customers from different industrial sectors, some of which are illustrated as below. HeatsinksHeatsinks are widely used in telecommunication products, power supply and audio devices for instance high quality speakers, amplifiers, equalizers, etc. Given the high thermal conductivity of extruded aluminium, computer manufacturers have gained tremendous advantage in utilizing heatsinks as heat dissipation device to reduce the internal temperature of its computers in which highly delicate electronic chips and microprocessors are placed. Miniature heatsinks are used in mother boards or display cards chipsets of other electronic components. Product PartsThe durability and light weight feature of aluminium are widely recognized by manufacturers of industrial , as well as domestic equipment. Advanced with these advantages, the Energizer hand torch manufactured by Sonca has found its outstanding name in the market worldwide. Aluminium extrusion is also welcome in other electrical appliances. Audio ComponentsThe application of aluminium is commonly found in making front panel, casing, etc of audio appliances and equipment. For this category of products, surface treatment and fabrication are the key, at which our specialists and their expertise are excellent. The non-magnetic characteristic of aluminium is also found fit as supporting parts of power supply products and wide ranges of electronic equipment. Tubes by Seamless ExtrusionThe rigidity and hardness of aluminium have significantly contributed in making tubes and pipes in different shapes and sizes for industrial, architectural and constructional usages. Our innovative extrusion process can suit many peculiar requests in shapes and styles of aluminium tubes and pipes ordered by our customers. Seamless extrusion can even satisfy the need for high pressure resistance and achieve high mechanical requirement product. Hoi Po has successfully produced normal extrusion and seamless extrusion with our new Seamless Extrusion Lines, Quenching Furnace, Tube Drawing and re-forming machines. Our latest facility development also enhance us to produce with 2xxx, 3xxx, 5xxx, 6xxx and 7xxx alloy. Skive Fins HeatsinksIn recent years, Hoi Po was devoted to perform researches in improving heat dissipation efficiency of heatsinks and finally achieved a patented design at the end of 2008. (China Patent No. 200720056708.4) The patent would be mainly on the subject of increasing the surface areas of the fins of the heatsinks in a homogeneous product design. The fins are hence modified using specially designated machines into different orientated shapes and of different angles in 3-dimensional matrix, including trapezoidal, triangular, rectangular or even wavy fins. The fins could be machined in different surfaces of the base as devised, while various bundles could be fabricated throughout the heatsink base length for further liquid or fluid cooling. 2014, Hoi Po was devoted to reaserch and development in skive fin heatsink technology and invested in new manufacturing equipment. Now the skive Fin can be processed with the width of 1000mm, fin height 100mm, length 4000mm, fin thickness 0.1mm-2.5mm and fin gap 0.2-6mm. Because of its unique manufacturability, our company can create a larger surface area to enhance the cooling performance within limited space. In the meanwhile, our company has developed Friction Stir Welding technology so that the width of the heatsink was no longer limited by the tonnage limit of extrusion machine. Hoi Po become a leader in the high-power heatsink field by combining the friction stir welding and the skive fin technology. *** Send inquiries now by clicking onto the pictures. Architectural ProductsAluminium extrusion is common in construction products. Door frames, window frames, tables, storage units, etc are only some examples in which both metallic appearance and durability of aluminium are displayed. |

|