Loading... Please wait...

Loading... Please wait...Our Newsletter

- Home

- QC

QC

|

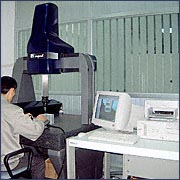

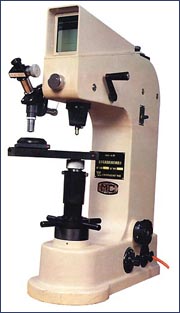

Every complete manufacturing plant should be equipped with a quality control system to warrant that output is in compliance with the expectations and standards projected. At Hoi Po, stringent quality measures are pursued to ensure stability in the process as well as quality of products manufactured. The implementation of ISO 9001 : 2000 unites both the Hong Kong office and the factory plant in China towards the same vision that is to achieve an international standard identified by local and global markets. Several quality systems in place at the respective production departments are as follows. IQC System:To assess raw materials such as ingots, billets, extrusion dies and sub-contractor pre-products IPQC System:To assess the extrusion, straightening, secondary machining and anodizing processes QA Process:To handle the after packaging of products With greater complexity in new products and higher expectation of customers, Hoi Po constantly research better methods towards the inspection of their output. The company have invested more than half a million in testing equipments that would enable the analysis of tensile strength, elongation, hardness, straightness, etc. CMM and projector serve in a good role in accurate measurement while spectrometer enhances chemical analysis of our raw material and products. Testing LaboratoryIn order to upgrade the product quality, Hoi Po has in house laboratory to practice different testings, aims to benefit our customers as more information and research results can be provided. Testing field- Physical Mechanical Properties ie Tensile Strength Hardness - Anodizing/Powder Coating Properties ie Coating Thickness Coating Impact - Thermo-resistance ie Testing heat dissipation of heatsinks - Chemical Analysis ie Chemical composition |

|