Loading... Please wait...

Loading... Please wait...Our Newsletter

- Home

- Extrusion

Extrusion

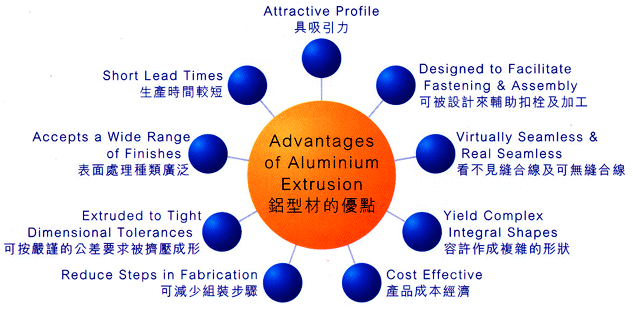

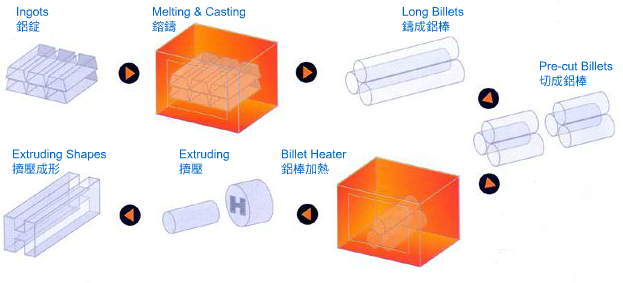

MeltingOur melting plant has equipped with 3 sets of aluminium melting furnace. Through different combinations of chemical components such as Silicon, Iron, Copper, Magnesium, Manganese, Chromium, Zinc, etc together with pure aluminium, various series of aluminium alloy can be formed. This include 2xxx, 3xxx, 5xxx, 6xxx and 7xxx series. Each kind of aluminium alloy will have their own chemical and mechanical properties in order to fulfill different product requirement. Hence, our product can penetrate into different market sectors. Mould Making and ExtrusionThe tooling workshop at the Hoi Po factory facilitates the Extrusion Department with the making of large varieties of mould or dies essential for the extrusion process. Out experienced personnel are supported by computerized machinery enabling efficient delivery of tools to expedite the production process resulting in shorter lead time. Extrusion Department is also equipped with 7 Presses which enable us to produce profile up to 210 mm wide. Some presses are also modified in order to produce special alloy product such as 2024, 7075 etc. Other secondary processing are also employed in the extrusion department such as quenching furnace, tube drawing, re-forming machines in order to satisfy different physical and mechanical requirements for clients. |

|

||||||||||||||||||

|

Extrusion Process with PLC ControllersWe have different scales of extrusion presses to produce various extrusion products. The following table shows the maximum cross-sectional diameter of the products that can be produced according to the billets used.

|

|||||||||||||||||||